AT5040 Studio Vocal Microphone

The fundamental operating principles of the condenser microphone are mature, well-established technologies that have been the subject of extensive theoretical analysis and development for decades. However, Audio-Technica engineers have long realized that there are still many areas in which condenser microphone element performance can be improved.

The fundamental operating principles of the condenser microphone are mature, well-established technologies that have been the subject of extensive theoretical analysis and development for decades. However, Audio-Technica engineers have long realized that there are still many areas in which condenser microphone element performance can be improved.

In creating our AT5040 side-address studio condenser, the first of our design criteria was purity of sound. We also focused on creating solutions to known issues that affect element performance, to develop a microphone that functions well beyond expected maximum performance limitations. While we have relied on proprietary Audio-Technica technologies that have proven effective in many of our other microphones, we are also introducing multiple design breakthroughs in the AT5040.

Audio-Technica's premier studio vocal microphone, the AT5040 cardioid condenser represents a milestone in condenser design, incorporating an innovative large-diaphragm element, the finest materials, and unsurpassed build quality.

Four-part Rectangular Large-diaphragm Element

We knew from the outset that the AT5040 would feature a large-diaphragm element, as we aimed to create a microphone that offered benefits often associated with large-diaphragm capsules: smooth, natural sound; low self-noise; high sensitivity; and increased presence. In fact, our engineers were determined to push the limits of diaphragm size to offer an extremely high signal-to-noise ratio and a marked increase in energy capture.

At the same time, we wanted to avoid the typical drawbacks of larger diaphragm sizes: limited high-frequency response, a potentially more rigid and less reactive diaphragm, temperature stability issues, and increased space between the back plate and the diaphragm that can impact sensitivity.

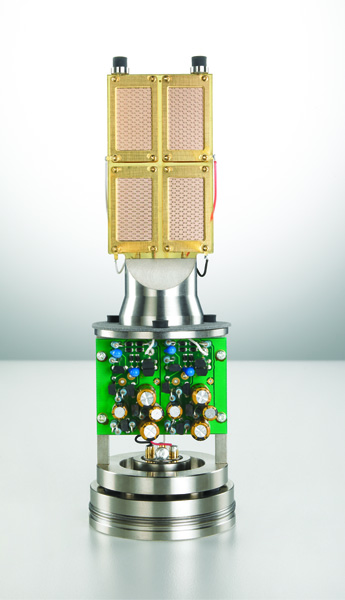

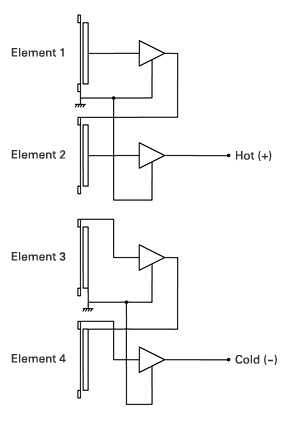

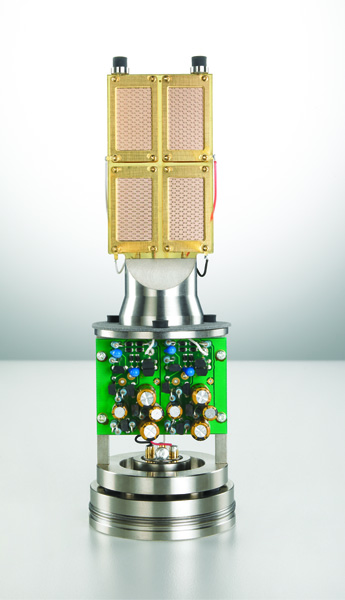

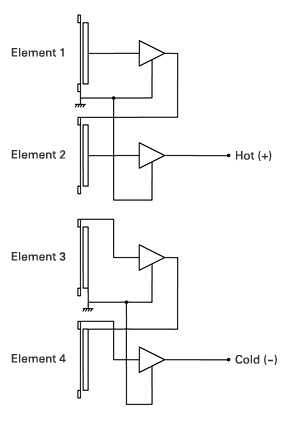

To address these issues, Audio-Technica engineers developed a four-part rectangular element, the pinnacle of our recent breakthroughs in sound-capture technology. In the AT5040, four rectangular elements function together as a single high-performance capsule, the largest that Audio-Technica has ever created. Their outputs are proprietarily summed in a patent-pending circuit design. And thanks to Audio-Technica's superb production process controls, the four elements are precisely matched an impressive feat in itself, and one for which Audio-Technica has long been renowned.

Each of the four individual elements offers 254.4mm² of effective diaphragm area. Thus, the total effective diaphragm area of the four elements combined is 1017.6mm². To achieve this conventionally, one would need an impractically large circular diaphragm element with a diameter of 36.0mm. (For comparison, this is more than double the effective diaphragm area of a one-inch capsule.)

The AT5040 unique element design offers spectacular advantages: an increase in diaphragm surface area allows for a natural increase in energy transfer, resulting in more realism, greater depth, increased presence, and profound purity of sound. It also offers much tighter directionality at the high end of the frequency range and an extended high-end frequency response up to 20KHz. By using four elements as a single capsule, the AT5040 delivers these benefits--along with an extremely low noise floor--without increased weight, decreased transient response or other drawbacks that typically restrict diaphragm size.

Audio-Technica research and development has demonstrated this four-part rectangular element provides the best way to obtain the maximum merit of a large-diaphragm microphone design without suffering the above-mentioned problem and issues. In addition to the obvious space-saving merits of the rectangular element shape, we found that by using this design we were able to increase the microphone's signal-to-noise ratio. Additionally, we discovered that with the rectangular element design, we could provide an improved and smoother 5k to 20k off-axis response than was possible using a conventional circular element.

Each AT5040 diaphragm is carefully engineered to improve transient response and increase response bandwidth. Each is 2 microns thick, vapor-deposited gold and aged so that the optimum characteristics remain constant over years of use. Each employs Audio-Technica's patented double wave honeycomb surface to increase effective diaphragm area and stability. In addition, each benefits from Audio-Technica's proprietary production processes control and equipment. These process control advances are not limited to the diaphragm assemblies, but also benefit many other important assemblies in the AT5040, such as the back plate, back cavities, acoustic resistance materials and more.

The back plate of each diaphragm holds a fixed charge and has been aged to provide energy stabilization and exacting charge linearity. This also benefits performance through a reduction in both frequency response peaks and diaphragm break-up distortion.

Advanced Circuit Design

To ensure optimum performance of the capsule, the AT5040's circuitry utilizes only discrete electronic components. Every component for the circuit board assembly is carefully selected based on its sound quality.

Our method of combining the outputs of four independent elements in this patent-pending design is quite unique.

By means of this proprietary summing method we have been able to quadruple the microphone's sensitivity to -25 dBv, while only doubling its noise level to a very low 5 dB SPL. This high sensitivity allows the AT5040 to function optimally with a wide range of microphone preamplifiers. All this while still providing significant headroom, enough to accept 142dB SPL at 1kHz of maximum sound pressure level.

Purity of the Audio Chain

With an eye toward purity, Audio-Technica engineers opted to use an electret design for the AT5040. While many feel that the electret cannot equal the performance of the DC bias condenser, Audio-Technica has developed production processes that fundamentally changed the condenser landscape and delivered the electret from second-best status. In fact, because of Audio-Technica's expertise in developing ultra-high-quality, impeccably consistent electret capsules, we were able to forgo the traditional DC-to-DC converters required by DC bias microphones. This is advantageous because the power needs of DC-to-DC converters divert current from the phantom power source. By eliminating the DC-to-DC converter we are able to obtain maximum circuit drive voltage for highest max SPL capability. At the same time, we are erasing the possibility of any audio anomalies to the signal chain that the DC-to-DC converter may impart.

In order to capitalize on phantom power, further extend the AT5040's dynamic range and maintain purity of sound, our engineers eliminated any unnecessary circuitry, which included forgoing the use of any switches or pads.

Precision Body Construction

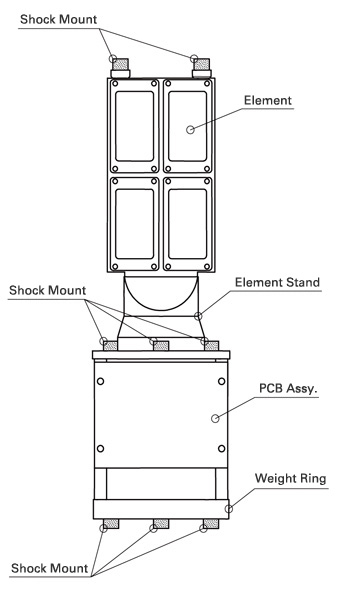

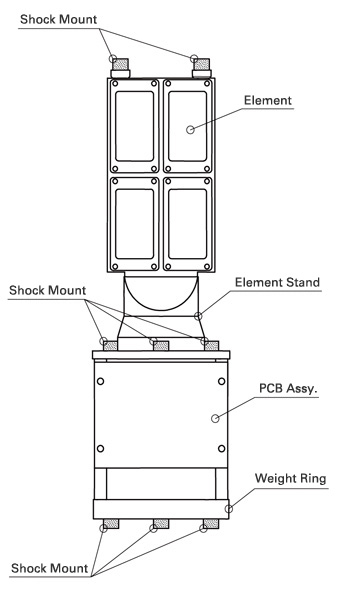

The internal structure of the capsule is a single unit, floating within an advanced internal shock mount that effectively decouples the capsule from the microphone body. The frame is inserted inside the headcase in order to increase rigidity and to further reduce handling noise.

The solid aluminum bottom body shell is threaded onto the top double-layered mesh grill assembly. To further reduce the potential for unwanted resonance, the two layers of mesh have been fused together. The element assembly and PCB frame assembly are individually floated and held by a dedicated shock mount. Thus the element assembly is isolated from external vibrations.

Since each part of the microphone body is rigidly connected and unified, we were able to eliminate the need for any components related to RFI countermeasures.

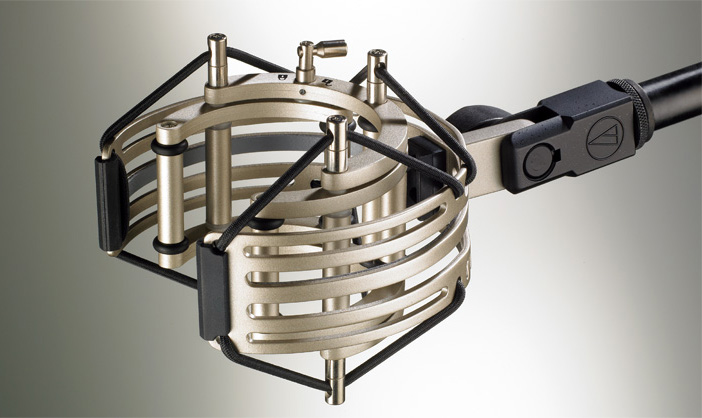

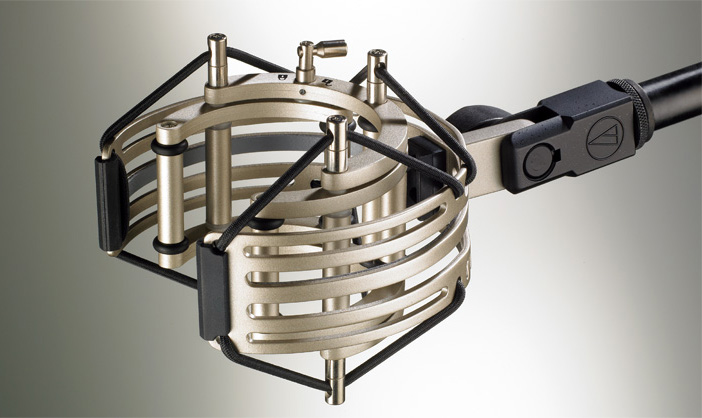

To further isolate the AT5040, the microphone is supplied with Audio-Technica's new shock mount, the AT8480. This proprietary design was engineered both to isolate the microphone and to eliminate any unwanted resonance or other audio aberrations that could be transmitted to it. The AT8480 also features a unique locking mechanism to hold the microphone securely in place.

100% Quality Control

Every AT5040 is hand assembled and inspected for 100% quality control. Each microphone is enclosed in an elegant housing of aluminum and brass with high-quality gray finish for durability and low reflectivity. Discrete components have been selected for optimized capsule performance; in fact, every aspect of microphone has been carefully considered to minimize any effects on the audio signal.

To protect the AT5040, each microphone comes in a custom-designed hard-shell carrying case, padded with die-cut foam compartments for the microphone and shock mount.

The fundamental operating principles of the condenser microphone are mature, well-established technologies that have been the subject of extensive theoretical analysis and development for decades. However, Audio-Technica engineers have long realized that there are still many areas in which condenser microphone element performance can be improved.

The fundamental operating principles of the condenser microphone are mature, well-established technologies that have been the subject of extensive theoretical analysis and development for decades. However, Audio-Technica engineers have long realized that there are still many areas in which condenser microphone element performance can be improved. To ensure optimum performance of the capsule, the AT5040's circuitry utilizes only discrete electronic components. Every component for the circuit board assembly is carefully selected based on its sound quality.

To ensure optimum performance of the capsule, the AT5040's circuitry utilizes only discrete electronic components. Every component for the circuit board assembly is carefully selected based on its sound quality.